Home » Products » Coating Inspection » Adhesion Testers » Pull Off Adhesion Tester » Elcometer 506 Pull Off Adhesion Tester

Elcometer 506 Pull Off Adhesion Tester

Product Description

The Elcometer 506 Adhesion Testers are lightweight, portable and easy-to-use adhesion testers available in analogue or digital gauges and are suitable for measuring the pull-off adhesion of coatings up to 50MPa either on-site, or in the laboratory.

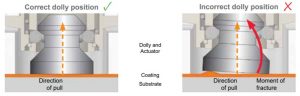

The design of the Elcometer 506 Adhesion Testers ensures that a uniform force can be easily applied throughout the range by smoothly rotating the gauge’s crank handle, ensuring repeatable adhesion results to an accuracy of ±1%

The Elcometer 506 adhesion tester’s quick connect coupling allows the simple attachment of 14.2mm, 20mm or 50mm diameter dollies which, together with a wide range of accessories, allows coating adhesion testing on flat, curved, thick and thin substrates – including metal, wood, concrete and other fibrous materials.

The Elcometer 506 test head (actuator) has been designed to be small, ergonomic and lightweight – ideal for single handed testing of coating adhesion even in awkward or confined spaces.

Safe adhesion testing on vertical surfaces has also been considered. Using the magnetic clamp accessory, the actuator is held securely – preventing accidental damage to the surrounding areas.

|

|

|

| Digital and analogue gauges available for both harsh and hazardous environments | Actuator skirts for a range of substrate thicknesses and bond strengths on flat or curved surfaces | Low height actuator allows access in restricted areas. Safety harness clip prevents accidental damage of surrounding areas during test on vertical surfaces. |

Features of the Elcometer 506 Pull-Off Adhesion Tester

Suitable for adhesion testing on metal, wood, concrete and other substrates.

Powerful

• Suitable for adhesion testing on metal, wood, concrete and other substrates.

• Rugged & lightweight – ideal for frequent testing

• Smooth load application up to 50 MPa

Accurate

• Measurement range is up to 50 MPa with an accuracy of ±1% of full scale

Flexible

• Easy to use hand-held design.

• Ideal for adhesion tests in the laboratory and the field

• 14.2, 20 and 50mm diameter reusable dollies

• Measures adhesion on small, curved and flat surfaces

Durable

• Sealed, heavy duty and impact resistant.

• Dust and waterproof equivalent to IP65

• Suitable for use in harsh environments

The Elcometer 506 Pull-Off Adhesion Tester can be used in accordance with:

• ASTM D4541

• ASTM D7234

• AS/NZS 1580.408.5

• BS 1881-207

• DIN 1048-2

• EN 12636*

• EN 13144

• EN 1542

• EN 24624

• ISO 16276-1

• ISO 4624

• JIS K 5600-5-7

• NF T30-606

• NF T30-062*

* Standards not in bold have been superseded but are still recognised in some industries.

Specifications

Elcometer 506 Pull Off Adhesion Tester – Specifications

| Part Number | Description | Certificate | ||||

| F506-20A | Elcometer 506 Analogue Adhesion Tester Kit; 20mm | ● | ||||

| F506-20AC | Elcometer 506 Analogue Adhesion Tester Kit; 20mm – Certified | ο | ||||

| F506-20D | Elcometer 506 Digital Adhesion Tester Kit; 20mm | ● | ||||

| F506-20DC | Elcometer 506 Digital Adhesion Tester Kit; 20mm – Certified | ο | ||||

| F506-50D | Elcometer 506 Digital Adhesion Tester Kit; 50mm | ● | ||||

| F506-50DC | Elcometer 506 Digital Adhesion Tester Kit; 50mm – Certified | ο | ||||

| Accuracy | ±1% of full scale | |||||

| Pressure Rating | 26 MPa | |||||

| 14.2mm Dolly | 20mm Dolly | 50mm Dolly | ||||

| Operating Range | 4 to 50 MPa | 2 to 25 MPa | 0.3 to 4 MPa | |||

| Scale Resolution | ||||||

| Analogue | 0.1 MPa | 0.1 MPa | 0.05 MPa | |||

| Digital | 0.01 MPa | 0.01 MPa | 0.01 MPa | |||

| Instrument Length | 290mm | 290mm | 290mm | |||

| Actuator Height (skirt fitted) | 85mm | 85mm | 110mm | |||

| Instrument Weight | 1.8kg | 1.8kg | 2.0kg | |||

| Kit Weight | 4kg | 4kg | 5.2kg | |||

| Battery Type | 2 x LR6 (AA) alkaline dry batteries (digital gauge only) Battery Life: 2000 hours | |||||

• Test Certificate supplied as standard

ο Calibration Certificate supplied as standard.

Packing List

- Elcometer 506 Adhesion Tester with dollies

- Standard Skirt for dollies

- Dolly cutter arbor & Dolly cutter

- Araldite Standard two part epoxy adhesive (2 x 15ml tubes)

- Abrasive Pad

- Carry Case

- 2 x LR6 (AA) batteries (Digital Gauge only)

- Test Certificate

- Operating instructions

Data Sheet

Elcometer 506 Pull Off Adhesion Tester – Data Sheet

Elcometer 506 Pull Off Adhesion Tester Data Sheet

Standards

Elcometer 506 Pull Off Adhesion Tester – Standards

The Elcometer 506 Pull-Off Adhesion Tester can be used in accordance with:

• ASTM D4541

• ASTM D7234

• AS/NZS 1580.408.5

• BS 1881-207

• DIN 1048-2

• EN 12636*

• EN 13144

• EN 1542

• EN 24624

• ISO 16276-1

• ISO 4624

• JIS K 5600-5-7

• NF T30-606

• NF T30-062*

* Standards not in bold have been superseded but are still recognised in some industries.

Accessories

Elcometer 506 Pull Off Adhesion Tester – Accessories

| Dollies | Part Number | Description | |

|

Dolly Diameter | Pack of 10* | Pack of 100 |

| 10mm | T5100014AL-10 | T5100014AL-100 | |

| 14.2mm | T9990014AL-10 | T9990014AL-100 | |

| 20mm | T9990020AL-10 | T9990020AL-100 | |

| 50mm | T9990050AL-4 | – | |

| 50mm Stainless Steel | T9990050SS-4 | – | |

| Dolly Skirts | Part Number | Description | |

|

Diameter | Standard Skirt | Thin Substrate Skirt |

| 10mm | T999101420S | – | |

| 14.2mm | T999101420S | T9990014T | |

| 20mm | T999101420S | T9990020T | |

| 50mm | T9990050S | – | |

| 50mm Stainless Steel | – | – | |

| Adhesion Verification Unit | |||

|

Part Number | Description | |

| T99923924 | Elcometer AVU Adhesion Verification Unit | ||

| T99923924C | Elcometer AVU Adhesion Verification Unit – Certified | ||

| Dolly Cutter | Part Number | Description | |

|

Diameter | Dolly Cutter Handle | Dolly Cutter |

| 10mm | – | – | |

| 14.2mm | T9991420H | T9990014CT | |

| 20mm | T9991420H | T9990020CT | |

| 50mm | T9990050H | T9990050CT | |

| 50mm Stainless Steel | – | – | |

| Magnetic Anchor Clamp | |||

|

Part Number | Description | |

| T99923797 | Magnetic Anchor Clamp – holds actuator securely during tests | ||

| on vertical surfaces | |||

| Adhesive | |||

|

Part Number | Description | |

| T99912906 | Araldite Standard Two Part Epoxy Adhesive, 2 x 15ml Tubes | ||

| Dolly Cleaning Heating Tongs | |||

| Part Number | Description | ||

| T99923147 | Dolly Cleaning Heating Tongs – EUR 220V / UK 240V | ||

Test Method

Pull-Off Adhesion Tests: Preventing Adhesive and Cohesive Failures

Preparing the surface and dolly

1. Select an appropriate test area which is flat and has sufficient area to attach the adhesion gauge.

2. Abrade the dolly and surface, clean both to remove any dust – minimising the risk of an ‘adhesive’ failure.

Fixing the dolly

3. Mix the adhesive correctly and apply a uniform adhesive film over the entire dolly face.

4. Test Standards require that the dolly is pulled off perpendicularly to the test surface. The dolly must therefore be adhered on to a prepared flat test surface (see images below). Apply an even pressure to the dolly to ensure that the dolly face is parallel to the test surface.

5. Remove any excess adhesive from around the dolly and allow to fully cure. Tape maybe required when applying dollies to vertical surfaces during the cure process.

6. If required, once the dolly has fully cured, score the coating around the dolly using the dolly cutter provided.

7. Attach the gauge actuator to the dolly and begin test.

Assessment of the Adhesion Test

For a valid pull test the coating must cover at least 50% of the area of the dolly face. If the glue fails and no coating is present on the dolly, or it covers less than 50% of the dolly face area, the pull-test is invalid and should be repeated. When the coating has failed within the layer leaving the same coating on both the dolly and the test panel it is known as a ‘cohesive failure’. ‘Adhesive failures’ occur when either the coating has failed at the interface with another coating (leaving a coating on the dolly and another coating on the substrate), or when the coating has failed at the substrate (leaving the coating on the dolly and the substrate bare). NOTE: If the glue fails at a value above the specification then it can be reported that the adhesion exceeded the specification for this individual test.

Coating Adhesion Testing on Concrete

Instruction Manual

Elcometer 506 Pull Off Adhesion Tester – Instruction Manual

Elcometer 506 Pull Off Adhesion Tester – Instruction Manual

Video

Elcometer 506 Pull Off Adhesion Tester – Video

When testing coating adhesion using a pull-off adhesion tester, there are a range of dolly sizes and gauge types to choose from; and your pull off adhesion test application will affect the dolly (tensile stub) or gauge you choose.

There are a number of pull off adhesion gauge design types. These include:

– mechanical gauges such as the Elcometer 106 (ASTM D4541 Type II);

– hydraulic push off gauges such as the Elcometer 108 and 508 (ASTM D4541 Type III);

– and hydraulic pull off gauges, such as the manual Elcometer 506, and the automatic Elcometer 510 (ASTM D4541 Type V) – which are available with various dolly skirts for the different dolly sizes or substrate thicknesses.

When it comes to choosing a dolly or tensile pull stub, whilst a 20mm diameter dolly is most commonly used to test coating adhesion on most substrates, there are different sized dollies for different applications.

When the adhesive value of a coating is expected to be very high, use a smaller sized dolly, as the smaller the diameter, the higher the achievable tensile force.

So 50mm dollies, for example, are designed for testing coatings on concrete or if the adhesion is expected to be very low.

14.2 and 10mm dollies, on the other hand, are typically used for testing small areas, curved surfaces, or when the adhesive value of the coating is expected to be very high.

All pull-off adhesion testers follow the same principle. A properly prepared dolly, or pull stub, is glued to the prepared coating, and, once the glue has fully cured, the dolly is pulled off -perpendicularly (or 90 degrees) from the surface. The resultant tensile pull-off force, together with the dolly diameter, and the conditions of the dolly, are all recorded.