Home » Products » Coating Inspection » Climatic Condition Testing » Infrared Temperature Thermometer » Infrared Thermometer » Elcometer 214 Infrared Digital Thermometer (Laser pointer)

Elcometer 214 Infrared Digital Thermometer (Laser pointer)

Product Description

The Elcometer 214 IR Digital Laser Thermometer is a simple, easy-to-use, non-contact thermometer which safely and accurately measures surface temperature of non-reflective materials using infrared technology. These versatile units can also be used to measure body temperature of humans.

With a user switchable measuring range of -35°C to 365°C a digital display of the temperature is produced in <1 second.

• Non-contact technology with laser spot indicator

• Fast, 1 second scanning of any surface

• Measure objects as small as 25mm

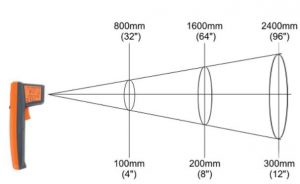

• Distance-to-Target Ratio of 8:1

• Easy to read LCD display

The Elcometer 214 IR Digital Laser Thermometer has a D/T ratio (Distance-to-Target) of 8:1 and measures the emitted energy from a target spot one-eighth the size of the working distance. As can be seen in the diagram, if the distance from the sensor optics to the target is 200mm for example, the diameter of the measured area is 25mm.

Specifications

Elcometer 214 Infrared Digital Thermometer – Specifications

| Part Number | Description |

| G214L—-3 | Elcometer 214 Infrared Digital Laser Thermometer |

| Measuring Range | -35°C to 365°C |

| Ambient Temperature | 0 to 50°C |

| Resolution | 0.2°C |

| Accuracy | ±1.5°C |

| Distance-To-Target | 8:1, 25mm spot size |

| Emissivity | Fixed at 0.95 |

| Response Time | 1 second |

| Battery Type | 2 x LR03 (AAA) |

| Battery Life | 14+ hours continuous use |

| Dimensions | 166 x 34 x 64mm |

| Weight | 113g |

Packing List

- Elcometer 214 Infrared Digital Laser Thermometer

- 2 x AAA batteries (fitted)

- Wrist Strap

- Operating Instructions

Data Sheet

Elcometer 214 Infrared Digital Thermometer – Data Sheet

Elcometer 214 Infrared Digital Thermometer (Laser pointer) Data Sheet

Instruction Manual

Elcometer 214 Infrared Digital Thermometer – Instruction Manual

Elcometer 214 Infrared Digital Thermometer (Laser pointer) – Instruction Manual

Video

Elcometer 214 Infrared Digital Thermometer – Video

If climatic conditions; such as surface temperature, air temperature, relative humidity, wet bulb temperature, dry bulb temperature, dewpoint temperature, and the Delta T; are wrong at the time of applying a coating, this could cause coating failure.

That’s why it’s vital to monitor a range of climatic parameters before and during the coating application process, to ensure your coating can have a successful service life.

So what climatic parameters do we measure, why do we measure them, and how?

Contents

0:00 – Introduction

0:50 – What climatic conditions do we measure?

1:48 – Why do we measure climatic conditions?

3:58 – How do we measure climatic conditions?

4:20 – How to use a Whirling Hygrometer / Sling Psychrometer

8:29 – Using a surface temperature thermometer

10:03 – Elcometer 319 Dewpoint Meter

The key climatic parameters include:

• Surface temperature (Ts), the temperature of the surface to be painted;

• Air temperature (Ta), the temperature of the air surrounding the surface to be painted;

• % Relative Humidity (RH), the amount of water vapour present in the air compared to the maximum possible, expressed as a percentage;

• Wet bulb temperature (Twb), the air temperature as read by a thermometer that’s covered in water-soaked fabric over which air is passed;

• Dry bulb temperature (Tdb), the temperature that is usually thought of as air temperature;

• Dewpoint (Td), the temperature at which moisture condenses on a surface, calculated from the air temperature and % Relative Humidity;

• And the Delta T (TΔ), the difference between the surface temperature (Ts) and the dewpoint temperature (Td).

While it’s important to monitor all of these parameters, special attention should be paid to surface temperature and relative humidity, as most paint data sheets will specify acceptable ranges of these parameters in which the paint can be applied.

However, by far the most important parameter of all is the Delta T, as it tells you the difference between the surface temperature and the dewpoint temperature. The smaller the difference, the more likely that moisture (or dew) will have condensed on the surface.

It is generally accepted within the industry that the Delta T should be at least 3°C or higher for the coating to be applied.

How do you actually measure and calculate the key climatic parameters? There are two main methods you can follow.

The traditional method requires multiple pieces of equipment to complete.

The first piece required is the whirling hygrometer, also known as a sling psychrometer, and it is used to measure the wet bulb and dry bulb temperatures. These temperatures are then used to work out the dewpoint and relative humidity. Elcometer provides two types of hygrometer, but they work in pretty much the same way.

Hygrometers consist of two liquid filled thermometers positioned side-by-side in a rotating body. One thermometer is covered with a fabric “sock” or “wick” connected to a reservoir (this measures your wet bulb temperature), while the other is uncovered (this measures your dry bulb temperature).

Once you have your results, typically conversion tables are then used to determine the relative humidity and dewpoint temperature, like the ones supplied with the Elcometer 116 Hygrometers. Alternatively, the Elcometer 114 Dewpoint Calculator provides a quick and easy way to determine these values, and we show you how it works in our Elcometer 114 video: https://youtu.be/HLbuapAnoqA

However you are still missing the all-important Delta T measurement, and to calculate this, you still need a surface temperature measurement – something a hygrometer can’t provide, meaning you’ll need a separate surface thermometer. Once you have your surface temperature, subtract your dewpoint temperature from it, and you have the Delta T.

However there is a quicker and simpler method, without sacrificing on accuracy.

The Elcometer 319 Dewpoint Meter is a digital gauge that can monitor and record all of the key climatic parameters simultaneously, telling you if conditions are suitable for painting. What’s more it can continuously monitor and log the conditions as you paint, and instantly alarm if one of the parameters falls outside of the specified range.