Home » Archive » Discontinued Products » Elcometer 5135 5155 Taber Rotary Abrasion Testers – Discontinued

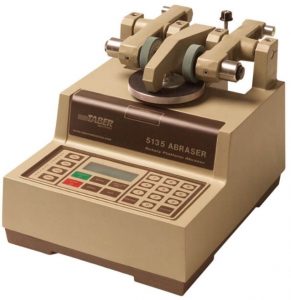

Elcometer 5135 5155 Taber Rotary Abrasion Testers

Product Description

The Taber® Rotary Abraser is an industry standard used in the wear and durability testing and is available with either a single test head or dual testing heads, which allows the user to test two different or identical materials simultaneously.

Used primarily in the testing of ceramics, plastics, textiles, metals, leather, rubber and painted, lacquered and electroplated surfaces, accelerated wear test procedures have also been written into many test specifications including ASTM, ISO, TAPPI and DIN – as well as automotive manufacturing procedures around the world.

Choose from a wide variety of abrading wheels and abraser accessories to simulate real-life wear conditions.

Features of the Elcometer 5135 & 5155 Taber Rotary Abrasers

• Platform speeds 60 and 72rpm

• Balanced, calibrated arms and wheel mounts

• Vacuum system with precision height adjustment

• Sealed aluminium housing with membrane control panel and digital display

The Elcometer 5135 & 5155 Taber Rotary Abrasers can be used in accordance with:

• ANSI

• AS/NZS

• ASTM

• BS

• DIN

• ECCA

• EN

• ENV

• FORD

• GM

• ISO

• JIS

• NEMA

• NF

• SAE

• SS

• TAPPI

• UNE

Specifications

Elcometer 5135 5155 Taber Rotary Abrasion Testers – Specifications

| Part Number | Description | Certificate | |

| Elcometer Taber® 5135 Single Head Abraser | Elcometer Taber® 5155 Dual Head Abraser | ● | |

| UK/EUR 230V | ST985135-2 | ST985155-2 | |

| Dimensions | 279 x 406 x 279 mm | 482 x 355 x 279 mm | |

| Weight | 19.5kg | 31.75kg | |

| Vacuum unit | 279 x 279 x 610 mm | 10.0kg | |

Data Sheet

Elcometer 5135 5155 Taber Rotary Abrasion Testers – Data Sheet

Elcometer 5135 5155 Taber Rotary Abrasion Testers Data Sheet

Standards

Elcometer 5135 5155 Taber Rotary Abrasion Testers – Standards

The Elcometer 5135 & 5155 Taber Rotary Abrasers can be used in accordance with:

• ANSI INCITS 322

• AS/NZS 1580.403.2

• AS/NZS 4266.2

• ASTM C1353

• ASTM C217

• ASTM C241,

• ASTM C501

• ASTM D1044

• ASTM D3389

• ASTM D3884

• ASTM D4060

• ASTM D6037

• ASTM D-7255

• ASTM F1478

• ASTM F1978

• ASTM F362

• ASTM F 510

• BS 5599

• DIN 52347

• DIN 53109

• DIN 53754

• DIN 53799*

• DIN 68861-2

• ECCA T16*

• EN 13329

• EN 13523-16

• EN 14323

• EN14327

• EN14354

• EN14431

• EN 14688

• EN 14864

• EN 1504-2

• EN 438-2,

• EN 660-2

• ENV 13696

• FORD BN108-02

• GM9515P

• ISO 10074

• ISO 14656

• ISO 24338

• ISO 3537

• ISO 4586-2

• ISO 5470-1

• ISO 7784-1

• ISO 7784-2

• ISO 9352

• JIS A 1453,

• JIS H 8503

• JIS K 5600-5-8

• JIS K 5600-5

• NEMA LD 3

• NF Q03-055

• SAE J 1530

• SAE J 1847,

• SAE J 365

• SAE J 948

• SIS 923509

• SS 923509

• TAPPI T 476

• UNE 135203-1

• UNE 48250

• UNE 56842

• UNE 5684

• UNE 56868

• UNE 57095

* Standards not in bold have been superseded but are still recognised in some industries

Accessories

Elcometer 5135 5155 Taber Rotary Abrasion Testers – Accessories

| Part Number | Description | |

| ST985500 | ||

|

Multi-Media Attachment This attachment is used to recreate contact surface wear caused by liquids, fluids and powders. Measures the abrasivity of materials including paints, pigments, adhesives, sealants, pastes, additives etc. If you require either the Elcometer Taber® 5135 or Taber® 5155 ready assembled with the Multi-Media Attachment, please contact Elcometer. |

|

| ST985000 | ||

|

Sample Cutter The Model 5000 Sample Cutter will cut a precise 106mm circular sample with a 6.35mm centre hole to prepare your specimens for use with the Elcometer Taber® Abrasers. An easy counter-clockwise cutting motion allows you to cut a variety of materials. Optional pads, which allow cutting thicknesses of 0.03mm to 6.35mm, are also available.

|

|

| ST980503-1 | Model 155 | |

| ST980503-2 | Model 255 | |

|

Grit Feeder Attachment Provides a unique method to evaluate 3-body abrasion resistance on a variety of materials. Aluminium oxide grit particles are evenly distributed on to the specimen wear path and pass under a pair of leather wheels. This loose grit acts as an abradant aiding the action that contributes to the physical breakdown of materials. The Abraser Vacuum is attached to the grit feeder and continuously removes both abraded material and used grit. The Grit distributor and vacuum removal nozzle heights are adjusted using a thumbscrew. Two versions are available, Model 155 and Model 255. The Model 155 uses an alignment guide screw to set the position of the instrument. The model 255 has an alignment block incoporated into the base to ensure the correct location of the grit feeder in relation to the Abraser. Both models are supplied complete with: |

|

| ST129497 | Complete 230V – both upper and base cabinets | |

| ST128372 | Complete 115V – both upper and base cabinets | |

| ST129498 | Base unit only 230V – includes vacuum unit | |

| ST128371 | Base unit only 115V – includes vacuum unit | |

| ST128370 | Upper unit only – work space and viewing window | |

|

Quiet Cabinet Comprising an upper and lower unit, this solid wood cabinet is suitable for use in a laboratory environment and achieves an approximate 20% reduction in operating sound level. The top cabinet provides a convenient, dust-free work space for the Abraser and features a Plexiglas® viewing window to monitor testing and a removable front for easy transfer of the Abraser in and out of the cabinet. The base cabinet holds the Abraser Vacuum Unit and includes an inbuilt exhaust system for effective air circulation. Both cabinets offer ample room to store test specimens, supplies and accessories. The Quiet Cabinet can be purchased as a complete unit or the top and base separately. The lower cabinet exhaust system is available for 230V/50Hz or 115V/60Hz. |

|

| ST132030 | Calibration Verification Kit | |

|

Calibration Verification Kit A cost effective method that enables users to verify that an instrument is in calibration, or requires attention. Each kit is individually calibrated providing a reliable check system. Kit allows you to verify:

Supplied complete with:

|

|

|

Taber Abrading Wheels and Wearasers See last page of the datasheet to choose from a wide variety of abrading wheels and abraser accessories to simulate real-life wear conditions. |

|